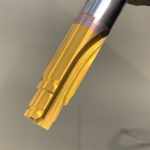

MCat

Our specially developed layer is optimally tailored to the needs of high-performance machining. Thanks to its nanocomposite structure, it achieves a high level of hardness and wear resistance, while its smooth surface enables very good chip removal.

Our specially developed layer is optimally tailored to the needs of high-performance machining. Thanks to its nanocomposite structure, it achieves a high level of hardness and wear resistance, while its smooth surface enables very good chip removal.

Application: hard-to-machine materials, fiber composite materials for the highest demands on hardness and temperatures

| MCat | Parameter |

|---|---|

| nano hardness (GPa) |

44 |

| coating thickness (µm) |

1,5 - 4 |

| friction coefficient against steel |

0,25 |

| maximum application temperature (°C) |

800 |

| color | dark copper |

TiALN

| TiALN | Parameter |

|---|---|

| nano hardness (GPa) |

36 |

| coating thickness (µm) |

1 - 3 |

| friction coefficient against steel |

0,5 |

| maximum application temperature (°C) |

700 |

| color | violet-black |

MB5

MB5 Is our high-performance sputtering layer to avoid built-up edges when machining sticky materials. The extremely smooth layer also meets the highest demands on the surface quality of the workpieces.

MB5 Is our high-performance sputtering layer to avoid built-up edges when machining sticky materials. The extremely smooth layer also meets the highest demands on the surface quality of the workpieces.

Application: Machining of Al alloys with low Si content, copper and titanium, optimization of PCD applications

| MB5 | Parameter |

|---|---|

| nano hardness (GPa) |

30 |

| coating thickness (µm) |

0,5 - 2 |

| friction coefficient against steel |

0,35 |

| maximum application temperature (°C) |

600 |

| color | light-grey |

MCro

| MCro | Parameter |

|---|---|

| nano hardness (GPa) |

36 |

| coating thickness (µm) |

1 - 3 |

| friction coefficient against steel |

0,5 |

| maximum application temperature (°C) |

900 |

| color | blue-grey |